Stress Corrosion Cracking

What is it?

Stress corrosion cracking (SCC), or environmental assisted cracking (EAC), is a problem that causes trans- or inter-granular cracking, which can lead to component failure. SCC is common in environments like seawater, ocean air, and sour wells It can also be in deficient concentrations of dissolved corrosive gases like chlorine, hydrogen sulfide, sulfur dioxide, carbon dioxide, etc.

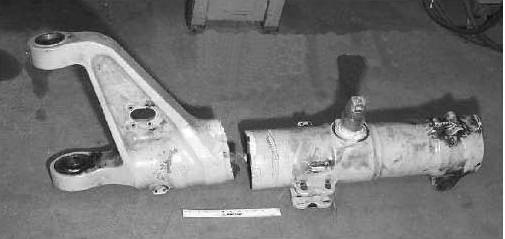

Why does stress corrosion cracking (SCC) cause failure in critical components?

SCC occurs in susceptible alloy-environments when static tensile stresses are present that exceed the threshold stress value for SCC cracking initiation. It’s common in high strength materials, like high strength aluminum and steels.

SCC is not fully understood. Mechanisms that might cause SCC failures to include rapid crevice corrosion along grain boundaries and the wedge opening of cracks by corrosion products.

How can you mitigate stress corrosion cracking (SCC)?

Complete isolation and control of these environments through protective coatings or surface treatments is nearly impossible due to possible scratching/damage and degradation over time.

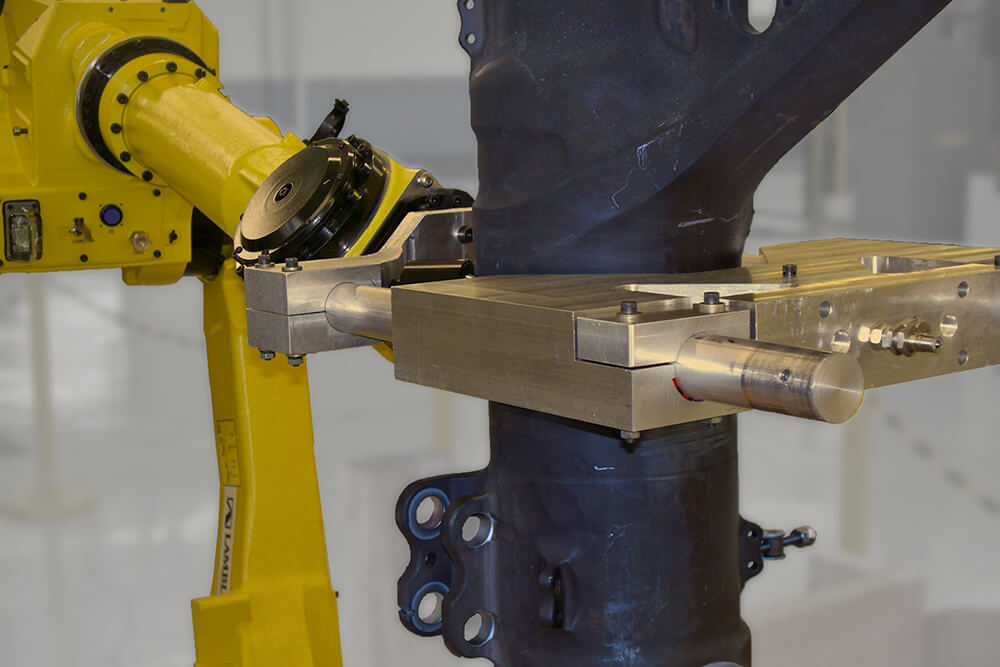

A deep, stable layer of residual compressions added to affected areas of components by using Low Plasticity Burnishing (LPB®). By putting vulnerable regions of compression combined with applied stresses to keep the surface stresses well under the SCC threshold stress and then cracks cannot propagate and eliminate the risk of failure.

LPB has repeatedly demonstrated its ability to hinder SCC and its cyclic variant, corrosion fatigue. General corrosion continues, but it eliminates the risk of catastrophic failure caused by SCC-driven cracks.

Learn more about Low Plasticity Burnishing from Lambda Technologies Group and how it can eliminate stress corrosion cracking in your critical metal components.