Non-Destructive Testing Services

What is Non-Destructive Testing?

Non-Destructive Testing (NDT) is an assortment of inspection methods aimed at evaluating inconsistencies in material properties without altering the integrity of the part. NDT provides an assessment of part and system integrity through the characterization of flaws and defects.

At Lambda, we can inspect metallic and non-metallic components with NDT services to detect discontinuities and differences in material characteristics.

How is it measured?

Lambda Technologies offers the following NDT Services for the field or laboratory.

- Eddy Current: An inspection method that uses electromagnetic induction to detect and characterize surface and near-surface flaws in conductive material. Near surface defects will disturb the path of eddy currents creating a measurable change in the voltage and phase of the exciting coil. This change in voltage and phase can indicate the presence of defects such as pitting, corrosion, or cracking.

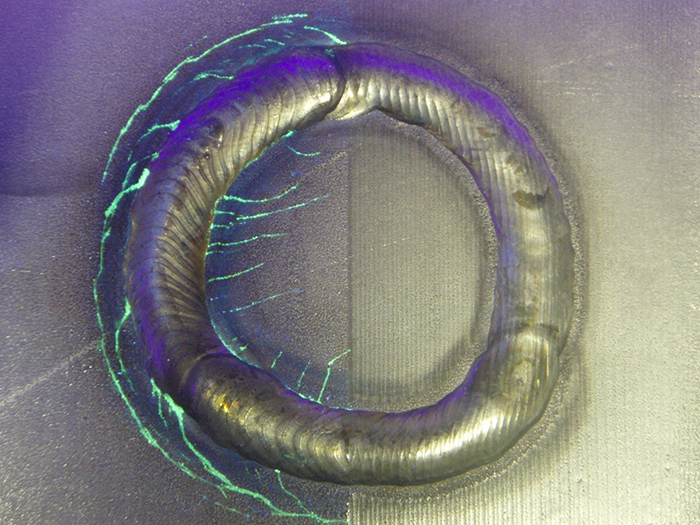

- Fluorescent Penetrant: A low-cost, dependable method for finding surface defects in casting, forging, and welding applications. A fluorescent or visible dye is applied to the non-porous material being tested. The penetrant is allowed to soak the material for a sufficient length of time and then removed. Then, using ultraviolet light, any remaining dye can be observed and indicate the presence of flaws.

Features:

- Eddy current inspectors certified to NAS 410

- Performed in the laboratory or field

- Minimal preparation for parts being tested

- Cost-effective and does not damage the component being tested, so it can potentially be repaired rather than replaced

How are Lambda’s Non-Destructive Testing Services Superior?

Lambda Technology Group has been studying materials for over four decades. Lambda is a name people trust with more than half a million completed measurements and 150+ years of combined experience. We are accredited by the American Association for Laboratory Accreditations (A2LA) in accordance with ISO/IEC 17025.