Foreign Object Damage

What is it?

Foreign object damage (FOD) is the formation of any nick or dent in the surface of a component or structure caused by something alien to the main system or vehicle. FOD is the nemesis of aircraft engines and structures, as well as ground-based turbines. It is usually produced by flying debris, but it can be caused by almost anything that compromises the quality or functionality of material. Some examples include tools or parts left where they shouldn’t be during maintenance, fragments or pieces of broken pavement, or birds or other wildlife.

Why does FOD cause failure in critical components?

The formation of any nick or dent in the surface of a component or structure that doesn’t have a high residual compression, produces a stress concentration factor. Stress concentration factors (SCF) start at 1.0 if material is flawless and would correspond to the highest fatigue strength. Higher SCF corresponds to lower fatigue strength. SCF for FOD can be as high as 5.0, depending upon the nature of the damage and the shape produced. This reduced strength can lead to catastrophic failure.

How can Foreign Object Damage be mitigated?

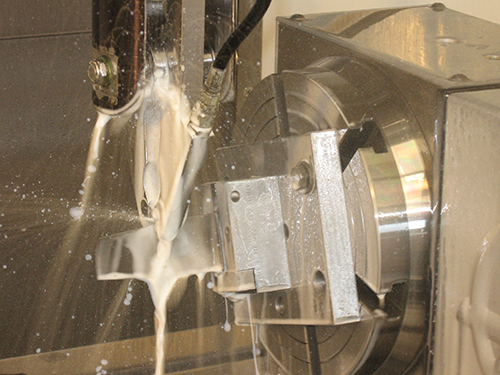

Introducing a layer of compression deeper than the depth of the FOD through a surface treatment method like Low Plasticity Burnishing (LPB®). This will impart beneficial compressive residual stress into the component and can completely mitigate FOD. Lambda Technologies Group has successfully demonstrated thisin many applications.

Learn more about Low Plasticity Burnishing (LPB) from Lambda Technologies Group and how it can prevent FOD in your critical metal components.

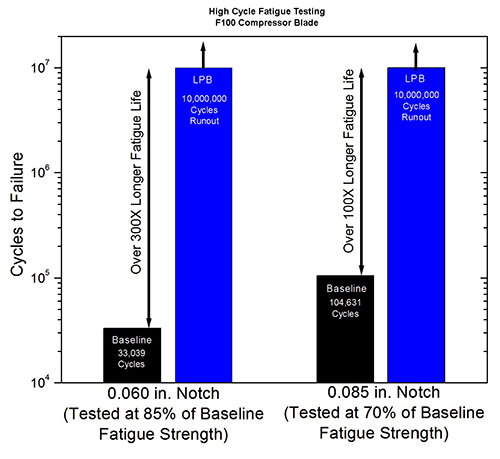

Fatigue Life Improvement of F100 Blade After LPB Processing