Corrosion Fatigue

What is it?

Corrosion fatigue is a type of metal fatigue. It occurs when a component is under repeated stresses or strains in a corrosive environment. This type of damage is common in aluminum and steels that come into contact with salt-water. Other commonalities are aircraft structures exposed to the elements, nuclear components, and welds, where stress corrosion cracking is a possibility. Intermittent exposure to even trace amounts of salt can rapidly accelerate fatigue cracking.

Why does this type of fatigue cause failure in critical components?

One of the most damaging aspects is that the corrosive component eliminates fatigue endurance limit. The damage of the component depends more upon time than stress cycles and reduces the safe threshold stress level. This can lead to rapid crack propagation, weakening the component with every cycle.

How can you mitigate corrosion fatigue?

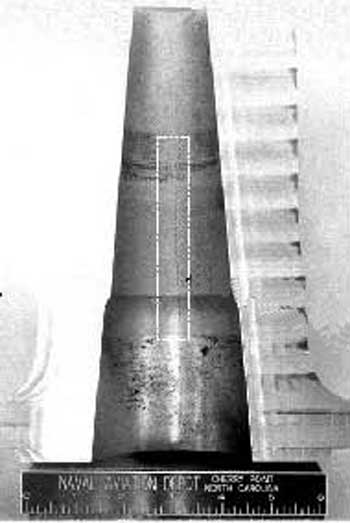

By introducing a deep, stable layer of compression with low cold work with a surface treatment method like Low Plasticity Burnishing (LPB®). This imparts beneficial compressive residual stress into the component and eliminates the stress corrosion component. The compressive residual stress holds the surface layer below the tensile stress threshold, thereby removing the cyclic stress corrosion component that accelerates fatigue failures in corrosive environments.

LPB has successfully mitigated this in many applications for almost any alloy. Request a quote and you can learn more about Low Plasticity Burnishing (LPB) from Lambda Technologies Group and how it can prevent corrosion fatigue in your critical metal components.