Lifing Analysis

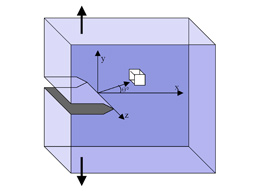

Lifing Analysis is assessing the design of critical components subjected to cyclic loading & the fatigue life of the finished part. Since fatigue cracks initiate at locations of peak tensile stress, usually from the surface of the part, the residual stresses located at and near the surface have a significant effect on the fatigue properties. Residual stresses are introduced by part manufacturing processes, including forging, casting, machining, heat treatment, welding, and surface treatment.

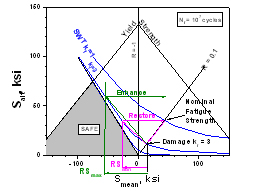

Residual stresses, however, do not have to be a side effect. Lambda’s theoretical lifing tools allow us to evaluate the benefits achievable through designed residual stress. Our patented Fatigue Design Diagram provides reliable estimates of life performance and the required residual stresses to combat fatigue.